|

FUN-Start

Mk2

1370mm Virtually

Crash-proof Slope Soarer Trainer

Designed

by Stan Yeo

Produced

by PHOENIX MODEL PRODUCTS

Introduction

The FUN-Start

Mk2 is designed as a low cost, low risk entry into radio control model

flying. Budding modellers with no previous model flying experience can,

after a short period of instruction, rapidly become accomplished slope

pilots. The FUN-Start Mk2 is a basic trainer with all the qualities expected

of a basic trainer plus the added bonus of being virtually crash-proof.

It is the fear of crashing that puts so many people off model flying and

inhibits those that do have a go. The model should only take a few hours

to put together and be within the capabilities of most people. So before

you start please read the instructions and throw away most preconceived

ideas about model building. This is not going to be a pretty model but

it does have a certain style! The EPP foam is glued using an impact adhesive

(Bostik or Evo-Stik) except for the mainspars which are glued with Epoxy.

Whilst the model is covered using glass reinforced cross weave (CW) tape.

A bit like over-protectively wrapping a parcel! Although it is strongly

recommended that before covering the model it is coated with a spray on

adhesive such as Stikatak Superspray (a carpet adhesive) to improve adhesion

between the cross weave tape and the foam. You have been warned so relax

and enjoy the experience!

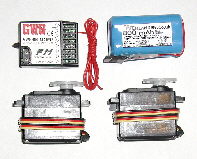

Radio

Control Equipment

If you are

starting from scratch and do not have the R/C equipment needed to fly

this model it is recommended you buy a 4 channel outfit with rechargeable

batteries and on a frequency of 35 Megahertz. We sell and recommend the

Hitec Laser 4 and the Futaba 6EXA. Both are very reliable and represent

excellent value for money. Check our website  phoenixmp.com

for details on price etc. For those looking to use existing equipment

or just buy new airborne equipment the FUN-Start Mk2 requires 2 standard

size servos, a square receiver battery (not the flat one normally supplied

with the set) and preferably a 4 channel receiver on 35mHz (please read

article on website Starting Slope Soaring). phoenixmp.com

for details on price etc. For those looking to use existing equipment

or just buy new airborne equipment the FUN-Start Mk2 requires 2 standard

size servos, a square receiver battery (not the flat one normally supplied

with the set) and preferably a 4 channel receiver on 35mHz (please read

article on website Starting Slope Soaring).

Tools

& Materials Required

The only

tools required are a modelling knife with spare blades and a 180 grade

Wet & Dry sanding block. Adhesives used are Spray Impact adhesive for

'foam' joints. Two part Epoxy for the wing mainspar and Superglue (cynoacralite)

for wood to wood joints

Building

the Fuselage

- Lightly sand ply fuselage side to remove splinters and release agent

used during the manufacture of the plywood. Please note it is likely

that the plywood sides will be distorted. This is unavoidable due to

the natural curvature of the wood and the technique used to cut the

parts out. If the problem is causing difficulties please contact us

for advice.

- Drill wing dowel holes in ply sides. If building trainer version

drill both sets of rear dowel holes ready for conversion to aileron

wing. Ensure a tight fit.

- Fit balsa strip longerons to ply sides using Superglue leaving gaps

for balsa blocks. Check there is a left and right side !!

- Cover plan with cling film and position fuselage sides above plan

view of fuselage, using wing dowels to assist with alignment. Position

balsa blocks. In conjunction with wing dowels use rubber bands stretched

over top of fuselage to position sides correctly. Use set square for

final vertical alignment.

final vertical alignment.

- Fit balsa block at front and rear of wing, plus block at fuselage

bottom under wing trailing edge (TE). DO NOT GLUE DOWELS, they are easier

to remove after an arrival!

- Fit nose former and join fuselage at tail. Fit ply tail seat. If

tailseat has bulged during die-cutting fit with bulge pointing inwards.

- Fit ply fuselage bottom forward of wing TE and ply top at nose, forward

of hatch.

- Spray with impact adhesive, one side of fuselage and one EPP foam

side and allow a couple of minutes for solvent to evaporate. Fit

foam

side to fuselage ensuring that the 'spare' is at the nose end (required

to form cavity for nose weight). foam

side to fuselage ensuring that the 'spare' is at the nose end (required

to form cavity for nose weight).

- Using sharp long bladed knife trim EPP foam ensuring that it is cut

square to fuselage top and bottom. Fit other EPP fuselage side and trim

as before.

- Decide which side of the servo the control rods need to be connected

for the controls to operate in correct sense. Remember control exit

is on opposite side. Insert piano wire push rod into control outer and

fit elevator control rod checking that pushrod moves freely. Anchor

to fuselage sides in two places between wing TE and tailplane using

balsa strip off-cuts or CW tape.

- Fit fuselage bottom again ensuring any surplus is at nose end.

- Fit EPP to nose top forward of hatch aligning with ends of EPP sides.

- Obtain a small sheet of roofing lead (scrap yard), preferably old

lead which is pure and not an alloy which is lighter). Cut out 4 off

33mm x 38mm sq. blocks and glue to front of nose former inside EPP foam

cavity. The FunStart requires at least 100grams of nose weight due to

its design.

- Fit noseblock and trim any surplus.

- Remove 1.5mm strip of plastic from Correx Tailplane and Fin along

hinge line to form hinge (as shown on plan).

- Fit, (using superglue) 10 mm triangular strip to base of Fin to line

up with tailplane as shown on plan. Check using set square that fin

is square when resting on base. Adjust as necessary.

- Mark tailplane centre on Correx and glue Fin in position using

Superglue ensuring it is square with the tailplane. TIP

If fin is not vertical after gluing to tailplane, cut balsa strip along

its length on inside of lean and insert sliver of thin card to correct

lean. When satisfied fix with Superglue.

Superglue ensuring it is square with the tailplane. TIP

If fin is not vertical after gluing to tailplane, cut balsa strip along

its length on inside of lean and insert sliver of thin card to correct

lean. When satisfied fix with Superglue.

- Cut fuselage top to shape above tailplane seat and relieve inside

of fin slot to accommodate 10 mm triangular strip at Fin base.

- Epoxy Tailplane to Fuselage ensuring that it is both square and in

line with the axis of the fuselage i.e. Fin has not got built-in left

or right rudder.

- Position fuselage top hot wire 'drill' hole for Rudder control rod

(use

non - Z bend end of push rod). Only heat the last 10 mm. Drill a test

hole in scrap EPP - you will be surprised at how easy the foam melts!

non - Z bend end of push rod). Only heat the last 10 mm. Drill a test

hole in scrap EPP - you will be surprised at how easy the foam melts!

- Fit rudder control rod and check for freedom of movement as before.

- Fit fuselage top. Trim to size as before and radius all corners using

a sharp knife and 'carving' action before final finishing with 180 grade

wet & dry. Manufacture hatch.

- Cover fuselage with CW tape (lengthwise). Lay first strips along

fuselage sides aligned with bottom of tailplane. Cover CW tape with

coloured vinyl to decorate model and protect CW tape from the effects

Ultra Violet light.

Building

the Wings

- Lightly sand wing including spar recesses with 180 grade Wet & Dry.

Check fit of spar recesses, adjust as necessary. Remove dust as

before. Laminate the ply dihedral braces.

before. Laminate the ply dihedral braces.

- Glue plastic trailing edge reinforcing to underside of wing trailing

edge.

- Epoxy lower wing spars in position. Place weights on wing panels

until epoxy set.

- Epoxy top spar and dihedral brace in position on one wing panel.

Weight down as before.

- Join wings ensuring they are set at the correct dihedral angle (170

-180mm). Epoxy top spar in position. Weight down as before until epoxy

set. Dihedral is important as not only it provide lateral

stability but also helps determine the effectiveness of the rudder.

stability but also helps determine the effectiveness of the rudder.

- Before covering spray model with spray adhesive such as Stikatak

Superspray or 3M Permanent Spray Mount.

- Lay 50mm wide strip of CW tape, the length of one wing plus 75mm

wing joint overlap, on a flat surface. Place the wing trailing edge

centrally on the tape and roll over the edges onto the top and bottom

surface of the wing. Smooth into position. Check trailing edge is straight.

Do same for other wing.

- Cover bottom surface of one wing. Starting at trailing edge and overlapping

centre section by 75mm and the previous strip by 8mm. Take care not

to introduce a twist into wing but please note that the wing has washout.

Washout is where the trailing edge of the wing twists up as it goes

towards the tip. Both wings should have the same amount of twist.

- Cover the top surface of the wing in a similar manner to the bottom

( see diagram).

- The CW tape degrades in ultra violet light (sunlight) so it is recommended

that the top surface of the wing and the fuselage is covered in an opaque

thin sticky back plastic tape which we can supply in a variety of colours.

We also advise that the model is stored away from direct sunlight any

other sources of UV light i.e. fluorescent lights.

Flying

Before attempting

to fly your FUN-Start Mk2 it is strongly recommended that you make contact

with the local model flying club and take out third party insurance. This

can is easily arranged through the British Model Flying Association (BMFA)

Tel: 0116 2440028 or Model Aviators Association (MAA) Tel 01472 242391.

Learning to fly can be a fraught process and prone to the occasional mishap,

particularly if going it alone, so if at all possible get an experienced

flyer to assist you during the initial flights. Unfortunately it is not

possible within these instructions to cover all aspects of model flying

but there are a number of articles on our website (phoenixmp.com) to assist

you. Below are a few basic key points.

- Be meticulous when setting up the controls. Ensure they operate in

the correct sense i.e. up is up and down is down. Check you have the

correct amount of movement i.e. +/ 9mm for the Elevator and +/- 35mm

for Rudder).

- Make sure the model balances at the correct point (despite the lead

built into the nose it may still require more weight). Failure to balance

the model correctly could make it almost impossible to fly. The FUN-Start

Mk2 will require several ounces of lead in the nose. This is normal

and helps to make the model more stable and able to fly in stronger

winds. In very strong winds it may be necessary to move the balance

point further forward of that shown on the plan.

- Lift to keep the model airborne is generated by the upward deflection

of the wind when it meets the face of the hill. No wind no lift!

- Gently launch the model into wind in a slightly nose-down attitude.

Do not give it a good chuck!

- Initially make all turns into wind. Do NOT turn towards the hill.

- Remember that when the model is flying towards you the rudder control

is reversed i.e. left rudder causes the model to turn to YOUR right.

- When turning, as soon as the rudder starts to turn the model allow

the control to return to neutral. Holding the rudder on during a turn

will cause the model to enter a spiral dive.

- Keep the fuselage level during the turn by using a small amount of

up elevator. This prevents a build-up of speed during the turn. Any

excess speed results in a zoom climb on exit from the turn.

- Before attempting aerobatics build up speed in a SHALLOW dive (20

- 30 degrees) otherwise the model will fail to complete the manoeuvre.

- With the FUN-Start Mk2 it may be necessary to add NOSE ballast in

windy conditions to assist with penetration and make the model more

stable.

- Always think SAFETY. Do not fly near overhead electricity cables,

close to busy roads or where the public are frequently crossing the

flying area. Be considerate to farm animals and avoid frightening them.

If flying from a site shared with other airborne 'objects' always be

extra vigilant.

The FUN-Start

Mk2 will take a lot of abuse and should prove an invaluable tool for those

wishing to become an accomplished model pilot. Having successfully, we

hope, assembled and flown the FUN-Start Mk2 why not try one of the more

conventional models in our range. There are over 20 to chose from (we

produce the largest range of everyday slope soarers in the country) and

it is being added to all the time. If you have any comments or suggestions

concerning any of our models or products please do not hesitate to contact

us. We like to hear from our customers.

Happy Landings

Stan Yeo

FunStart Mk2 030514

|