|

About Us

About Us

Read

about PMP's history and philosophies

What We Sell

What We Sell

View a full listing of products sold by PMP

Shopping at PMP

Shopping at PMP

An

overview of shopping at PMP

Newsletters Newsletters

Come Visit Us

Come Visit Us

We

are always happy for modellers to drop in and shop. Here are directions,

give us a call to let us know you're coming.

Agents/Suppliers for:-

Agents/Suppliers for:-

|

|

Rico

- SHE & Rico - SHE LW

60in EPP

Crash Resistant Pylon Racer / Sports Aerobatic Slope Soarer

Designed

by Stan Yeo

Produced

by PHOENIX MODEL PRODUCTS

Introduction

The Rico-SHE

is a stylish 60in EPP pylon racer I sports aerobatic sloper designed to

meet the demand for more crash resistant pylon racers and conform to the

new 6Oin EPP pylon racing class. It is intended that Rico-SHE is built

with wing mounted aileron servos with the ailerons being used as flapperons

with elevator flap coupling. In this mode Rico-SHE can perform must aerobatic

manoeuvres including outside loops, horizontal eights and sustained inverted

flight etc. As with all EPP models building time has been kept to a minimum;

typically 8 -12 hrs depending on the skill and care taken. Field repairs

are of the Elastoplast variety! Tools / Materials Required The only tools

required are a modelling knife with spare blades, a pair of sharp scissors,

180 grade Wet & Dry sanding block, a tube of impact adhesive such as Evo-Stik,

some runny super glue (please observe safety precautions on packets!),

epoxy and a soldering iron.

R/C

Equipment

The R/C Equipment used in the prototypes consisted of three metal gear micro servos (HS81MG) a 2/3 AF size Rx flat Nicad pack plus a Webra 6/

JR R700 7 channel Rx. All the items are available from PMP at competitive

prices.

micro servos (HS81MG) a 2/3 AF size Rx flat Nicad pack plus a Webra 6/

JR R700 7 channel Rx. All the items are available from PMP at competitive

prices.

Building

the Fuselage

- Lightly

sand the fuselage sides, top and bottom with 180 grade wet and dry to

remove the 'release' agent. Remove dust with a small brush or vacuum

cleaner. NOTE: If building the lightweight fuselage attach wingseat

reinforcement to inside of fuselage sides. Also the top balsa blocks

attached to these doublers are 1.5mm shorter than the front fuselage

blocks.

- Drill

wing dowel holes in fuselage sides and fit fuselage distance pieces

and nose former to one fuselage side.

- Fit 4.5mm

sq. strip, tail seat and triangular nose strip to fuselage. Check you

have a left and right side!

- Join

fuselage sides together over plan ensuring fuselage is straight. Cut

nose top to length and fit.

- Cut fuselage

top to length and glue in position.

- Fit elevator

servo to balsa bearers and determine which side of servo the elevator

pushrod needs to be for the elevator to operate in the correct sense!

Position inside fuselage. Dry fit elevator control rod. Position elevator

servo in fuselage and cut elevator pushrod level with hinge line of

elevator minus 45mm or 1.75inches to allow for threaded adaptor and

metal clevis.

- Remove

pushrod and fit outer sleeve if not already fitted and fit the second

elevator push rod to primary push rod as per the plan.

- Fit threaded

adapters and metal devises. DO NOT use locknuts on devises.

- Refit

elevator pushrod. Reposition servo and anchor pushrod conduit to fuselage

side near the conduit ends ensuring there is sufficient

control rod movement and does not bottom out at the push rod 'Y' joint.

- Do not

glue elevator servo in position until after the tailplane is fitted.

- Fit fuselage

bottom and trim to length. Drill hole for ballast bolts. Reinforce corner

joints with 25mm wide strips of CW tape.

- Spray

the fuselage and EPP sides with spray on adhesive. When solvent has

evaporated fit together and trim EPP flush with side but the nose former.

Here 10mm is left on all four sides to form a cavity for nose weight.

At the tailplane seat trim the EPP to the Vee tail angle.

- Trimming

the EPP is best done with a long bladed (X-Acto or similar) knife using

the fuselage top & bottom as a guide.

- Fit the

EPP fuselage bottom as before and trim the EPP again using fuselage

side as knife guide.

-

Fit EPP fuselage top (Front & Back). Round fuselage corners.

- Glue

6ograms or 2 ozs. of lead to front of nose former in cavity formed by

EPP sides. Fit nose block and shape fuselage i.e. round corners using

sharp knife and 180 grade wet & Dry (use dry!).

- Mark

centreline of tailplane and remove a triangular strip from top side

to allow tail to bend to 120 degree angle. Superglue balsa tail gusset

in position to lock tailplane at required angle.

- Mark

elevator hinge line on tailplane and remove strip of plastic on one

side to form hinge.

- With

hinge line uppermost, mark centre line of tailplane and cut V slot to

allow Tailplane to be folded to 120 degree angle. Super glue balsa triangular

TP centre brace in place.

- Glue

tailplane to fuselage using Epoxy.

- Make

hatch, shape and cover with CW tape.

- Cover

fuselage using CW tape. Overlap each strip by 6 - 10 mm or 1/4 to 318

inch. In high stress areas such the under the wing leading and trailing

edges apply an extra layer of tape for added strength.

Building

the Wings.

- Lightly

sand wing surfaces and remove dust as before. Trim and sand spar slots

to accommodate mainspars. Unfortunately cutting tapered wings with spar

slots result in a tapered spar slot. Remove waste from wing brace slot.

- Fit top

wing spars using Epoxy. Cut to length.

- Fit 3mm

bass trailing edges using Epoxy. Use masking tape to hold in position

whilst Epoxy sets.

- With

wing upside down fit wing brace and bottom wing spars. Note trailing

edges should form a straight line i.e. not be swept back or forward.

Trim spars to length and shape wing tips.

- Laminate

ply rear wing braces and Epoxy in position noting orientation of taper.

- Mark

position of wing servos (plan drawing is full size. Outboard position

of servo is dependant on servo lead length. Note servo arms both point

outboard of wing.

- Cut rectangular

hole for servo in wing ignoring servo mounting lugs. Note it may be

necessary to remove the mounting lugs of the servo.

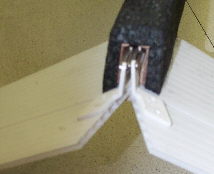

- Using

Hacksaw blade cut slot in EPP for servo lugs and fit servo so

that it is flush

with bottom of wing. Note gap between top of servo and top of wing.

From block of EPP removed for servo from wing slice off the required

amount and fit in this void.

- Remove

wing servos for covering.

- Spray

wing with spray adhesive and cover wing with GW tape. Start by laying

strip along TE. Then work forward overlapping the previous strip by

6-10mm. At the leading edge trim tape as you would if covering in film

but overlapping top and bottom by 10mm. Cover top surface of wing with

coloured vinyl tape I lightweight Fablon or iron on film. This serves

two purposes, one to decorate model, the second to reduce the effects

of ultra violet light on the CW tape.

- After

covering fit aileron servos. Cut vertical slot in wing to hide servo

leads.

- Cut ailerons

to size and shape aileron leading edge. Note the ailerons are top hinged

using Diamond Sellotape. Cover the ailerons, starting at TE using either

an iron on film or coloured vinyl tape used to decorate wing.

- Using

scrap wing sleeving manufacture wing fairing, cover and

double

side tape in position. double

side tape in position.

- Fit control

linkages and adjust to obtain required throws (see flying section).

DO NOT replace the plastic mini-snaplinks with metal devises. In the

event of a mishap the plastic snaplinks will break thereby reducing

the risk of damage to the aileron servos.

Performance

Tweeks

A number

minor of 'modifications' can be made to the Rico-SHE to enhance the model's

performance for competition and sports flying. They are not listed as

standard as most sports flyers would opt for durability and the simple

approach.

- The Correx

tail can be replaced with 4.5mm balsa sheet and the angle reduced to

110 degrees to marginally improve directional stability at the expense

of longitudinal (pitch) stability. If the Correx tail is replaced with

balsa we recommend that it is bolted on and a spare is carried rather

than being glued on as any damage to the tail could easily result in

the model being decommissioned.

- The aileron

hinge gap can be sealed with Mylar strip (draughting film) and aerodynamic

shrouds fitted over the aileron push rods.

- A bolt

on wing system can be used instead of rubber bands.

- Appropriate

ballast is used whenever the conditions permit but

please remember that if carrying ballast allow a little more airspace

to carry out manoeuvres and avoid over control.

- Couple

the flap and elevator so that when turning or looping etc. the wing

can produce the extra lift required more efficiently.

- By far

the biggest impact on a model's performance is the pilot! Practice makes

perfect. Fly Rico-SHE in as wide as conditions as possible and as often

as possible, with and without ballast.

Flying

- Set the controls to give the following movements for initial flights:

- Ailerons +/- 12 mm

- Elevator +/- 8 mm

- Flapperons +/- 5mm

- Balance Point 75mm +1- 5mm from LE

- Adjust balance to within recommended limits. Prototypes required

50 - 8ogms of lead in the nose. Check alignment of wing and tailplane

and wing to tailplane incidence (chord lines should be parallel). Laterally

balance wing and check that it is not twisted. If the wing is twisted,

twist back in the required direction and re-smooth covering tape in

position. If model is fitted with flapperons check zero flap is in fact

zero flap otherwise performance will be impaired!

- Depending on the control functions installed will depend the aerobatic

potential of the Rico-SHE. Remember all aerobatic manoeuvres require

energy to perform a manoeuvres. If the model has insufficient speed

it will fall out of the manoeuvre or perform it half-heartedly. Vertical

or near vertical dives are not an efficient way to build up speed, 20-

30 degree dives are much more efficient. Avoid sudden control inputs.

In most cases all they do is scrub off speed and lose height. Try to

fly smoothly with the minimum of control input as not only do the manoeuvres

look better but you will be able to perform more of them before having

to regain height. Try stringing manoeuvres together paying particular

attention to positioning. Be creative and set yourself targets for each

flying session.

- To check the elevators have no in-built rudder trim carry out a series

of loops into wind and note whether the tail remains into wind and or

attempts to 'screw out of the loop. Adjust elevators individually as

necessary.

- If the lift is good or you are having difficulty penetrating into

wind try ballasting the model. This will increase penetration and help

the model maintain speed through manoeuvres. Note when adding ballast

take care not to disturb the balance point. We have found the optimum

ballast to be 8 ounces or 225 grams. Take care when adding ballast as

over-ballasting can lead to tip stalling and a degradation in performance.

- The suggested control settings are a starting point and can be adjusted

to suit your personal tastes. Adjust the balance point so that when

the model is trimmed the elevator is more or less in the neutral position.

An indication that it is about right can be gauged by the amount of

down elevator required to maintain inverted flight. Please remember

if the balance point is moved from the design position it will alter

the elevator neutral position and will necessitate re-rigging the tailplane

to return the elevator to neutral.

- If you are using a computerised transmitter program in positive Exponential

on the Aileron and Elevator controls. This will 'soften' the controls

around the neutral position and facilitate smoother flying particularly

on the elevator control.

- Rico-SHE will take a lot of punishment. It is excellent for building

confidence and will add another dimension to your flying but please

remember if you take a big enough hammer to anything it will break particularly

the lightweight fuselage version. The CW tape used for covering also

degrades in ultra-violet light so store the model in a relatively cool

place away from direct sunlight.

- The RGI5 wing section is very efficient and performs well in light

lift so with good ballast selection Rico-SHE will cope with most wind

I lift conditions.

- Finally should you require further assistance or advice please contact

us either by letter, telephone, email or visit our website (http://www.phoenixmp.com)

where you will find useful information on sloping etc.

Happy flying

Stan Yeo

Rico-SHE

010130

|

|